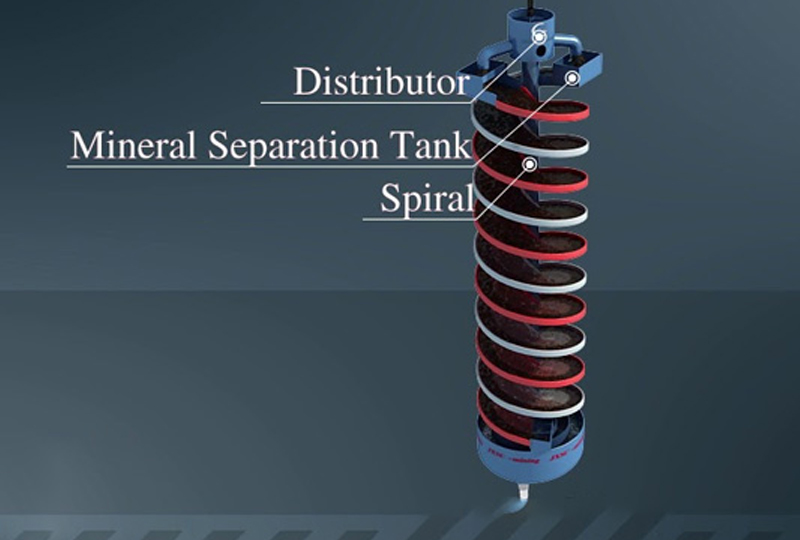

Spiral concentrator, also known as mineral spiral separator, spiral concentrator, spiral concentrator, gravity spiral concentrator, is suitable for recycling various fine minerals, improving resource utilization, and rationally and effectively developing and utilizing mineral resources.

The spiral concentrator is suitable for sorting fine iron ore, copper ore, chromite, aluminum ore, pyrrhotite, hematite, tungsten ore, tin ore, gold ore, and other non-ferrous metals and rare metals with different specific gravity. The spiral concentrators produced by FTM are divided into four types: DL2000, DL1500, LL1200 and LL900. You can purchase them according to your actual needs.

The spiral concentrator is installed vertically, and the ore is pumped from the sand to the two feed ports on the top of the spiral concentrator to adjust the density of the slurry. The ore pulp is naturally fed from high to low, and inertial centrifugal force is generated in the rotating inclined flow velocity.

According to the specific gravity, particle size and shape of the ore, the ore is separated by the gravity and centrifugal force of the cyclone separator. The concentrate flows into the concentrate hopper, which is connected with the pipeline. The tailings flow into the tailings hopper, are connected to the sand tank through pipelines, and are discharged by the sand pump. The whole beneficiation process has just been completed.

The spiral concentrator has a small footprint, moisture proof, antirust, corrosion resistance and no noise.

It consumes little water and electric power and has a large processing amount and low investment cost.

The ore dressing is stable; the mine is clear, and the recovery rate is high.

Magnetite Ore Dressing Plant in Brazil

Gold Ore Processing Plant in Zimbabwe

Gold Ore Processing Plant in Zimbabwe

Technical Specifications

| Model | Processing capacity (t/h) |

| DL2000 | 15-40 |

| DL1500 | 8-16 |

| LL1200 | 4-6 |

| LL900 | 2-3 |

Spiral Classifier

READ MORE

Spiral Classifier

READ MORE

Shaking Table

A gold shaking table (also known as gold gravity separation) is a commonly used beneficiation device for sorting fine-grained materials in minerals according to their density. The sorting precision is high.

READ MORE

Shaking Table

A gold shaking table (also known as gold gravity separation) is a commonly used beneficiation device for sorting fine-grained materials in minerals according to their density. The sorting precision is high.

READ MORE