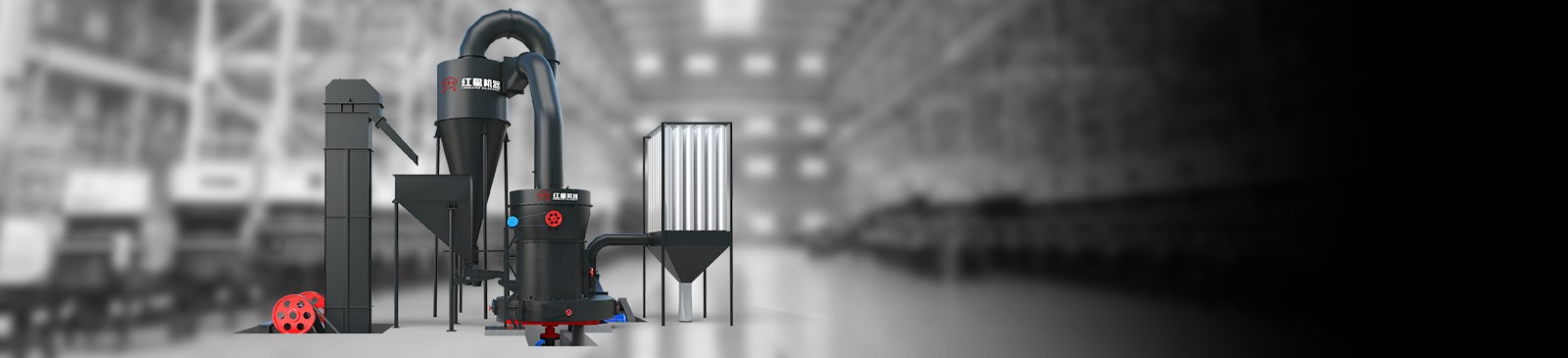

Raymond mill is widely used in high-fine powder processing of more than 280 kinds of non-metallic ore materials with a Mohs hardness of not more than 9.3 and non-flammable and explosive mineral, chemical and construction industries with a humidity of 6% or less.

It is suitable for---barite, calcite, potassium feldspar,talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, cement, phosphate rock, gypsum, etc.

The finished product has a particle size of 80-325 mesh and the size can be arbitrarily adjusted. Some materials even can reach 600 mesh.

Less occupied space, convenient transportation, installment, operation, and maintenance for the new-type design of the structure.

It adopts PLC electric automation control system, decreasing the failure rate and cost of the labor force, to achieve high production about power.

The fineness of the grind can be adjusted between 80-800 mesh, with a more flexible and extent fitness for use.

Made of high manganese steel with long service life. All the motors brands are national standards.

Raymond mill's main engine transmission adopts a sealed gearbox and pulley, which has a stable transmission and reliable operation.

Compared with other grinding types of equipment, the new model pass rate is up to 99%, which is impossible for the old type.

Technical Specifications

| Model | Output Size (mm) |

Shift output of different materia fineness(t) |

| 4525 | 0.173-0.044 | 16-176 |

| 4119 | 0.173-0.044 | 8-78 |

SFLM Series Ultra-fine Vertical Grinding Mill

SFLM series ultrafine vertical grinding machine is based on HLM vertical grinding machine, combined with related technologies from Germany,

READ MORE

SFLM Series Ultra-fine Vertical Grinding Mill

SFLM series ultrafine vertical grinding machine is based on HLM vertical grinding machine, combined with related technologies from Germany,

READ MORE

HLM Series Vertical Grinding Machine

HLM series vertical grinding machine is a large advanced and energy-saving grinding product developed by Hong xing Group using the world's advanced bed grinding and some external technology, combined with more than 40 years of grinding and manufacturing experience of Hong xing Group.

READ MORE

HLM Series Vertical Grinding Machine

HLM series vertical grinding machine is a large advanced and energy-saving grinding product developed by Hong xing Group using the world's advanced bed grinding and some external technology, combined with more than 40 years of grinding and manufacturing experience of Hong xing Group.

READ MORE